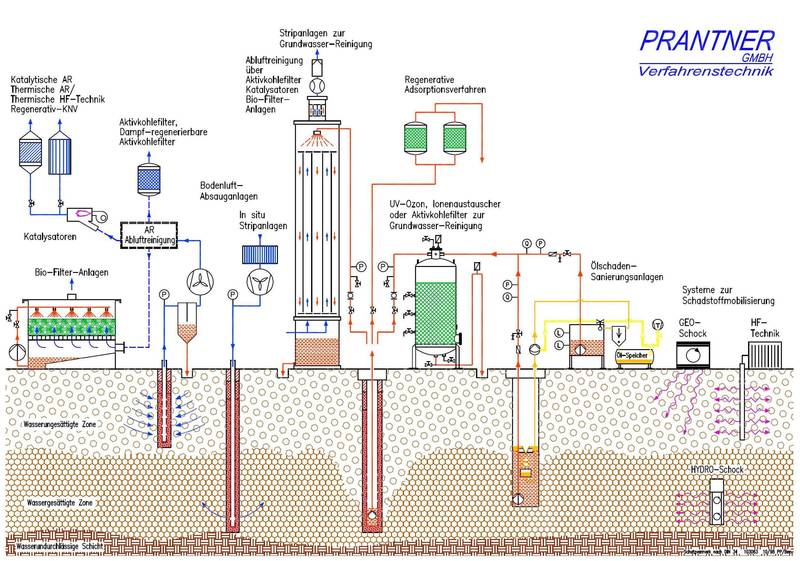

For the clean-up of contaminated soil Prantner can provide soil vapour extractionunits (Type BDL). In this process the pollutants are removed from the soil by sucking them out with a vacuum.

Prantner offers soil vapor extraction systems (BDL) for the purification/ aeration of contaminated soils. Volatile pollutants can be eliminated from soils by suction.

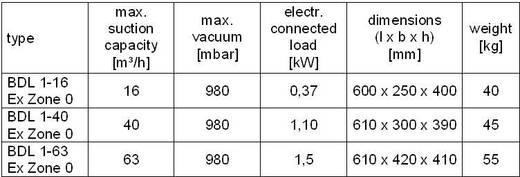

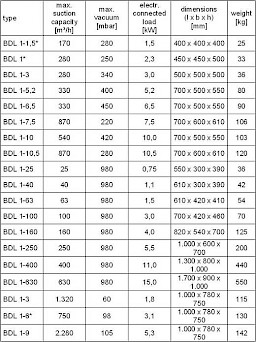

Standard systems have an aspiration volume of 25 to 2,300 m³/h with electrical connection values of 1,3 kW to 15 kW. The system covers the vacuum range of 0 to -980 mbar. Depending on the geological situation (soil condition) and the pollutant situation, Prantner provides different systems that are also available with perfect explosion protection.

For well drained soils we recommend the use of radial fans (0 to -20 mbar), for medium drained soils side channel compressors (0 to -400 mbar) and for poorly drained soils vacuum pumps (0 to -980 mbar).

For soil vapor extraction tests we offer you suitable equipment for rental. Upon your request, we perform soil vapor extraction tests and provide you with detailed evaluation results for further remediation planning.

Our service includes accessories such as water separators in automatic and manual design, tubes of all kinds, sound insulation, rain covers, air flow meter, vacuum gauge, pressure control valves, concentration measurement devices for incoming and outgoing air, interval control devices, air purification systems, and dilution equipment for reducing the pollutant concentration.

To save energy and cost, Prantner also provides soil vapor extraction systems that are interval-and concentration-controlled. Please feel free to request an offer.

Image: Explosion-proof high vacuum extraction system:

Simultaneous extraction of water, hydrocarbon phase, 800 m³/h of soil vapour and 3 m³/h of liquid phase

Standard sizes

Soil vapor extraction systems with explosion protection